Researchers in Singapore have found a less environmentally damaging way to produce perovskite solar cells in a laboratory, removing the need for the lead which had previously been used.

Scientists at Nanyang Technological University in Singapore (NTU Singapore) have replaced the traditional capping layer on a perovskite solar cell – which had resulted in the production of toxic lead – with a zinc-based capping layer.

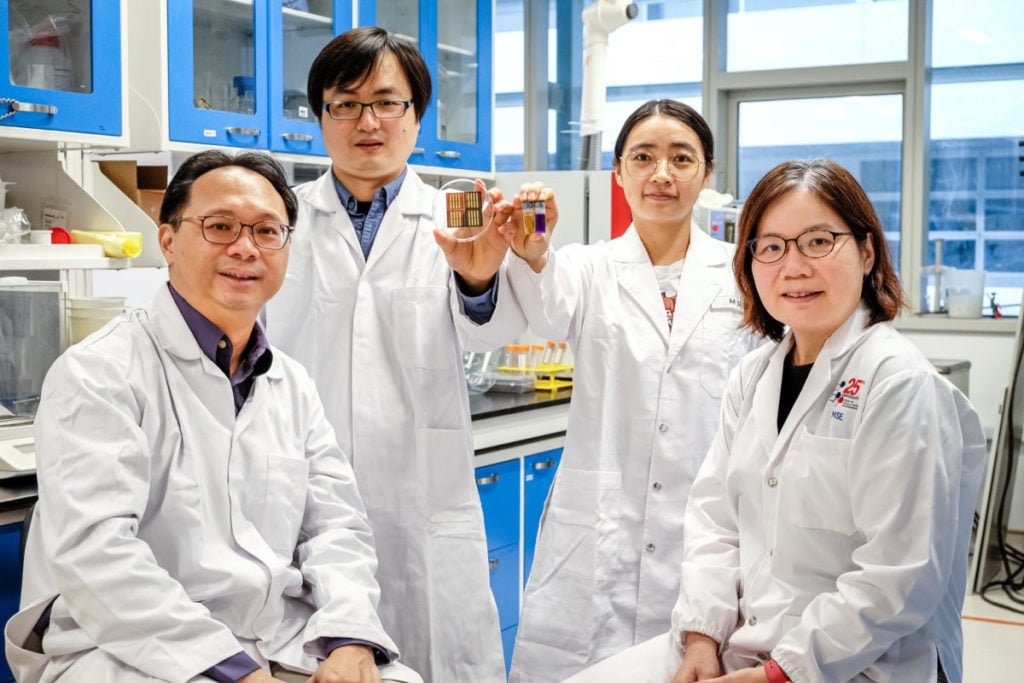

The testing resulted in a one-inch squared perovskite cell capped with a zinc compound, which examination showed to be effectively sealed and the perovskite unaffected by the compound layer. The researchers, led by Professor Sum Tze Chien and Professor Lam Yeng Ming, said that this represents a step to making perovskite solar cells both more environmentally friendly and more feasibly produced at industrial scale.

“One of the biggest drawbacks of using perovskite solar cells is their impact on the environment. By enabling zinc and other non-toxic metals to be used in the capping layer, our innovation potentially solves a major obstacle that prevents the widespread use of perovskite solar cells,” said Dr Ye Senyun, research fellow from NTU’s School of Physical and Mathematical Sciences.

The researchers also said that this zinc innovation opened the door to other materials and compounds that could be developed to improve the performance of perovskite cells.

Despite their record efficiency levels and performance, perovskite cells have yet to be manufactured at scale due to their unsustainable degradation levels when exposed to oxygen, moisture and light. This degradation is also what led the researchers to their concerns that lead could escape from a damaged cell – albeit in very small amounts – and pollute the surrounding environment.

Tests and accompanying efficiency results for perovskites emerge from laboratories around the world; researchers at the Australian National University posted a 30.3% efficiency rating earlier this month for a silicon-perovskite tandem cell, and the world record for perovskite efficiency is currently held by Helmhotz-Zentrum Berlin, a research institute that claimed a 32.5% efficiency on a 1cm squared cell.

Half-precursor vs. Full-precursor

The ‘traditional’ method of producing a perovskite cell capping layer uses a half-precursor (HP) method. One precursor chemical is put onto the perovskite layer to form part of the protective cap, whilst the other is formed through a reaction between the first precursor and the perovskite, drawing lead ions up from within the perovskite layer to form a lead-based capping layer.

The NTU Singapore scientists devised a full-precursor (FP) method, whereby the capping layer is fabricated with chemicals that react directly with one another and then applied to the perovskite layer. A zinc-based compound is made with zinc halide salts and PEAI, dissolved in a solvent called acetonitrile, then applied to a rapidly spinning perovskite layer. The layers are then heated to seal them and bind the perovskite and capping layer together. This avoids the use of toxic lead by removing the need to chemically extract it from the perovskite.